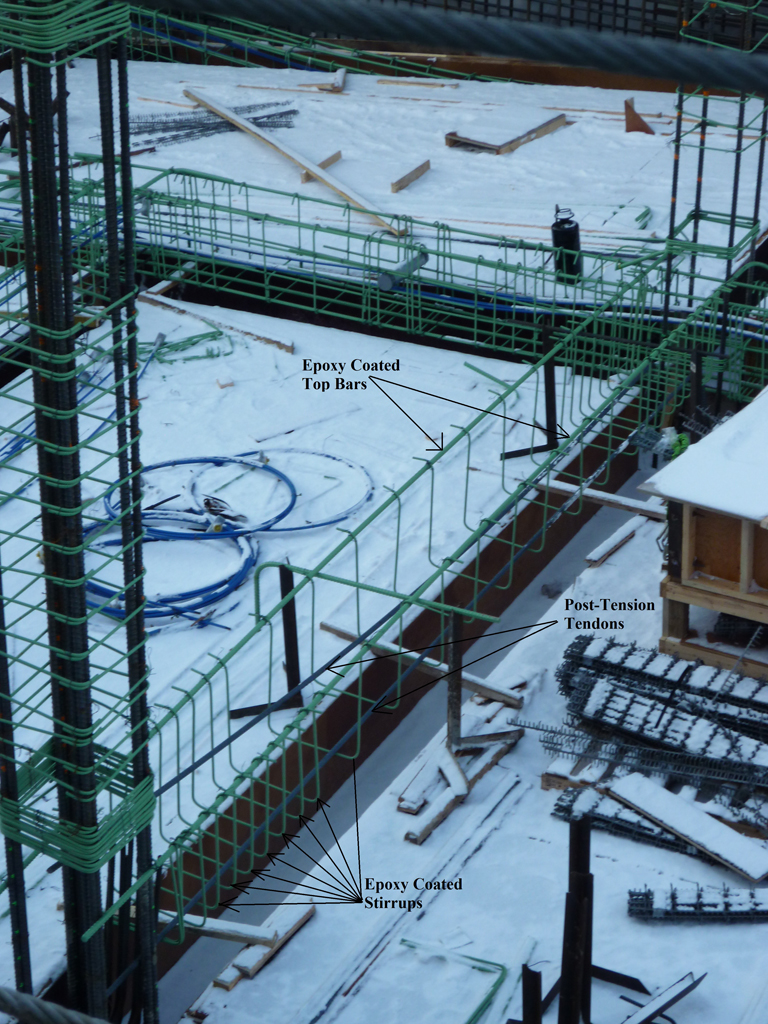

Photo Credit: Alex Mead

Seen here is the renovation of the University of California – Berkeley football stadium. Due to the spread out nature of a stadium type construction site, four tower cranes are needed to gain access to the project in its entirety. When dealing with tower cranes in this density great care must be taken to ensure that the booms of each crane do not interfere with each other. This is done with a combination of offsetting the height of each tower cranes as well as constant communication between the operators and the personal on the ground via radios.